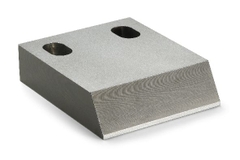

Flowmeter for volumetric filling machines

- High-stability zirconium oxide measuring tube

- Extreme long-term stability

- Most compact and lightweight design in the market

BATCHFLUX 5500 C is the industrial standard for volumetric filling machines.

Its zirconium oxide liner guarantees extreme long-term dimensional stability and therefore no change in repeatability of filling volumes over long periods of time.

The BATCHFLUX 5500 C is the successor to the BATCHFLUX 5015 C. The BATCHFLUX 5500 C offers some major improvements for the most commenly use sizes: DN10 and DN15. It has a better versatility of applications with a much better performance in difficult applications like fibrous products, hot filling and CIP / SIP processes.

Another improvement is that KROHNE has been able to further reduce the dimensions and weight of the flowmeter. It now fits in tighter spaces. The weight of filling machines can be reduced and energy savings are possible.

The BATCHFLUX 5500 C has en extreme low energy consumption. For the owner of the filling machine this means lower operation costs.

Highlights

- Design enables high speed filling with minimal product loss

- High level of filling accuracy

- Long term reliability due to extreme high dimensional stability

- Low power consumption of only 3 W

- Hygienic construction

- Easy to clean.

- CIP and SIP proof

- Absolutely leak-free stainless steel housing concept (DN10 and DN15)

- Application versatility

- 3A approval, FDA compliance (DN2.5...15)

Industries

- Food & Beverages

- Chemical

- Pharmaceutical

Applications

- Carousel and linear filling machines

- Water

- Soft drinks

- Milk

- Beer

- Fruit juices and other fluids with fibres

- Hot fillings up to 140°C / 284°F